MS-100A SERIES

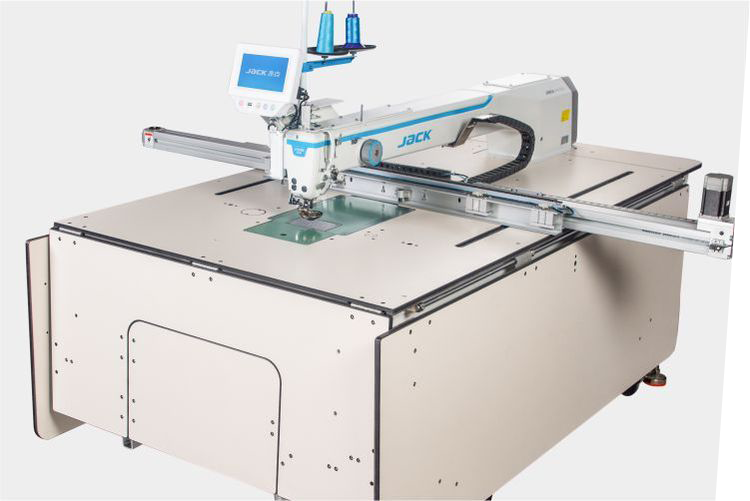

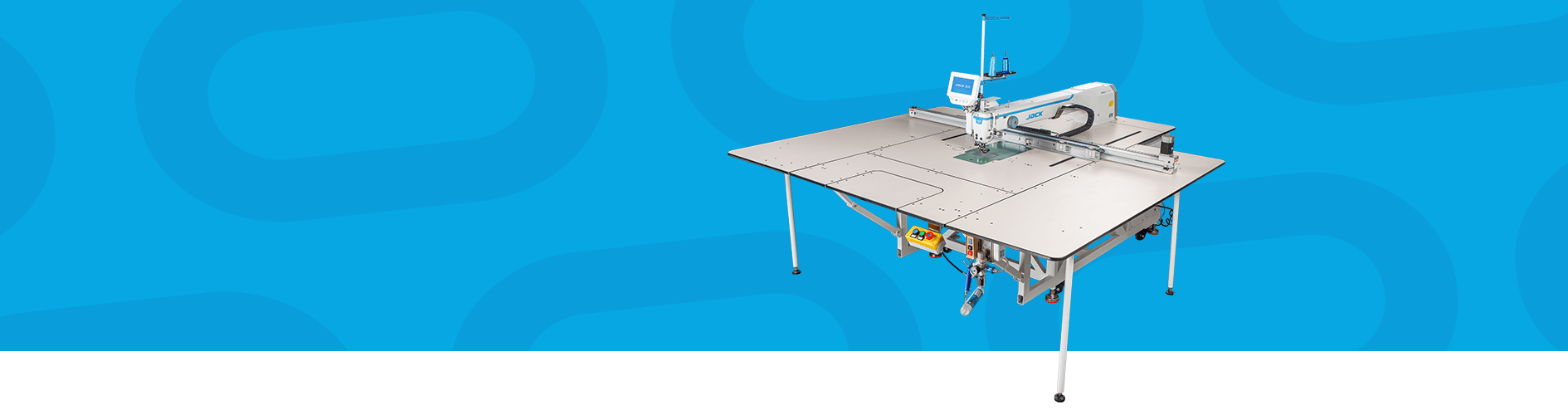

JACK Automatic Machine MS-100A

Electronically controlled machine JACK MS-100A for sewing large elements according to a programmed pattern in the sewing area: 1400 x 950 mm.

The machine is used to repeatedly perform a repetitive decorative sewing pattern, sewing on labels, Velcro, emblems as well as sewing in pockets, flaps, zippers and other elements. The machine can also be used in the production of quilted jackets, coats, quilts or mattresses.

Equipped with a servo motor built into the machine head (Direct Drive system) and stepper motors. The machine is applicable to various materials and operations, it is easy to use and thanks to the applied solutions it does not require special skills from the operator.

The machine is factory-fitted with a bobbin break sensor.

All sewing parameters can be programmed on a readable, touchscreen operation panel. Created patterns can be saved in the internal memory of the machine (available memory for 999 patterns) or an external USB memory.

Technical parameters:

- sewing speed: up to 2800 revolutions / min

- presser foot lift: up to 15 mm

- stitch length 0.1 – 20 mm

- needle system DPx5

- 230V power supply

- connection to the compressed air system required

| Model | Needles | Number of needles | Number of threads | Sewing area (mm) | Presser foot lift (mm) | Sewing speed: stitches / min |

|---|---|---|---|---|---|---|

| MS-100A | DPx5 / DPx17 | 1 | 2 | 1400 x 950 | 15 | 3000 |