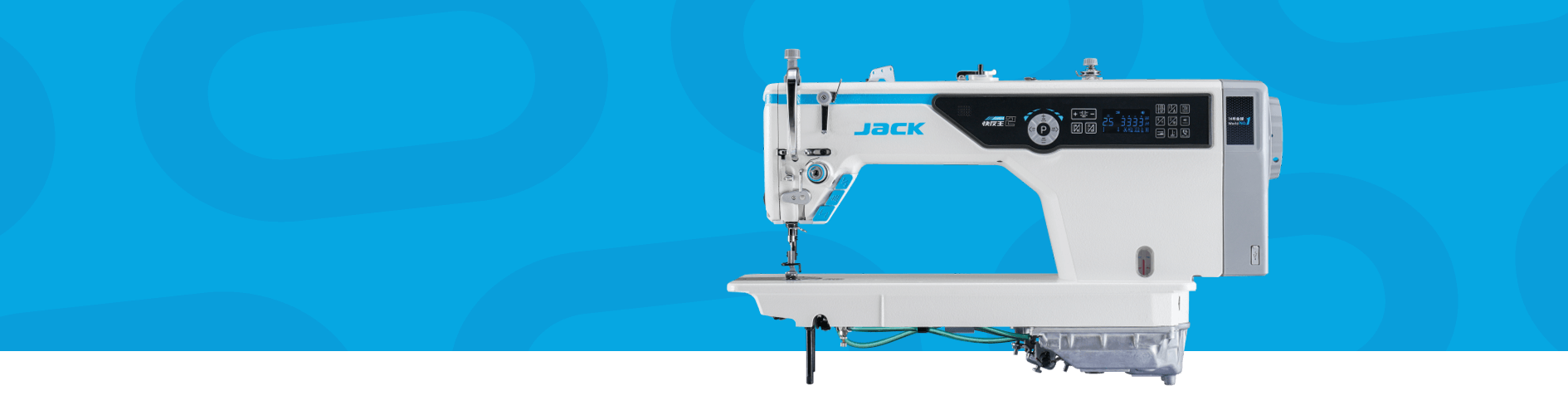

A5E-B SERIES – is the latest series of lockstitch machines with an innovative system that adapts the work to the sewn materials

JACK A5E-B Lockstitch

A single-needle lockstitch machine with automatic functions, bottom feed, and an energy-saving motor built into the machine head (Direct Drive). Like previous A5 versions, the machine features an elongated body – the distance from the needle to the body is 30.5cm.

Automatic functions:

- thread cutting

- lifting the presser foot

- bartacking while sewing

- needle positioning

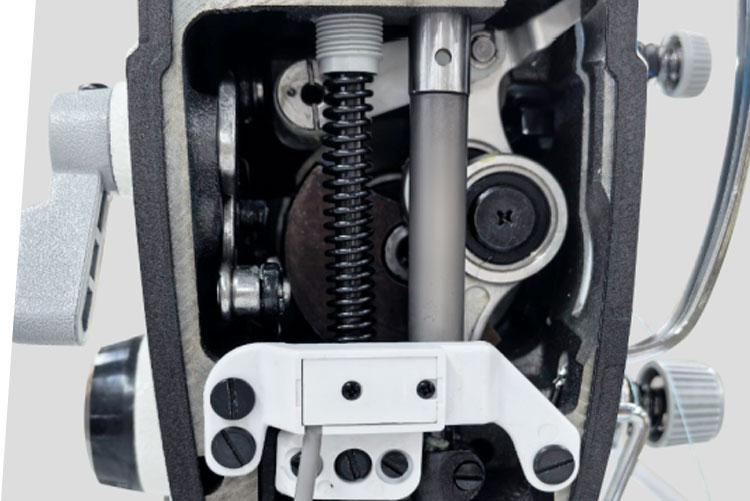

- semi-dry head

The machine uses a stepper motor that controls the stitch length setting and the bartacking function. The Octopus Dual-Core AI chip is an improved intelligent solution that automatically adjusts machine parameters in real time to the thickness of the material being sewn.

A more powerful motor with increased torque guarantees adequate penetration force even when sewing multi-layered, thicker materials. The Jack A5E-B lockstitch machine features a thread trimmer system that shortens the thread length after trimming to 3.5 mm.

Three function buttons are located near the needle bar: 1/2 stitch length, add stitch, and bartack. A USB port allows you to connect external devices.

Technical parameters:

- sewing speed: up to 5000 stitches/min (up to 3500 stitches/min – version H-7 and 7)

- stitch length: up to 5 mm (up to 7 mm – version H-7 and 7)

- presser foot lifting height: up to 13 mm

- three function buttons located near the needle bar: 1/2 stitch length, adding a stitch, bartacking

- USB port for connecting external devices

| Model | Needle system | Number of threads | Stitch length (mm) | Presser foot lifting height (mm) | Sewing speed stitches/min | Thin materials | Medium materials | Thick materials |

|---|---|---|---|---|---|---|---|---|

| A5E-B | DBX1 11-18# | 2 | 5 | do 13 | 5000 | V | V | |

| A5E-B-N | DBX1 11-18# | 2 | 5 | do 13 | 5000 | V | V | |

| A5E-B-H-7 | DPX5 18-21# | 2 | 7 | do 13 | 3500 | V | ||

| A5E-B-7 | DPX5 18-21# | 2 | 7 | do 13 | 3500 | V | V |

Extended Machine Body

The enlarged working area allows for sewing larger materials – the distance from the needle to the body is 30.5 cm.

“Octopus Dual-Core AI” chip

The Octopus Dual-Core AI artificial intelligence chip intelligently perceives and responds to changes in the thickness of the sewn material in real time.

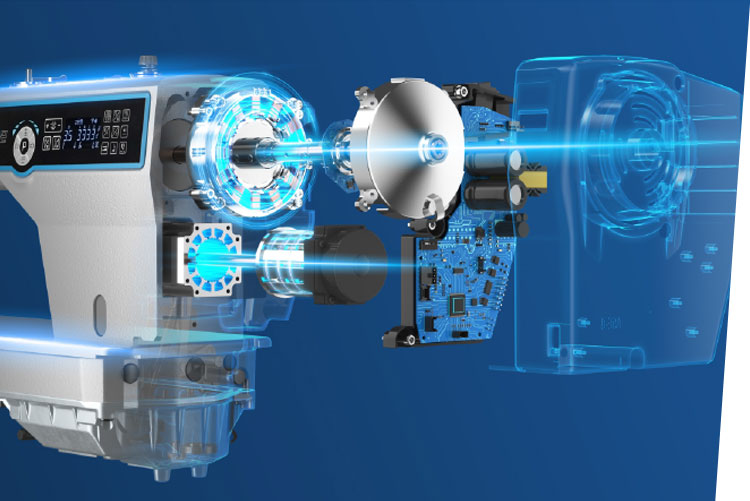

Increased Power Engine

High torque and increased engine dynamics.